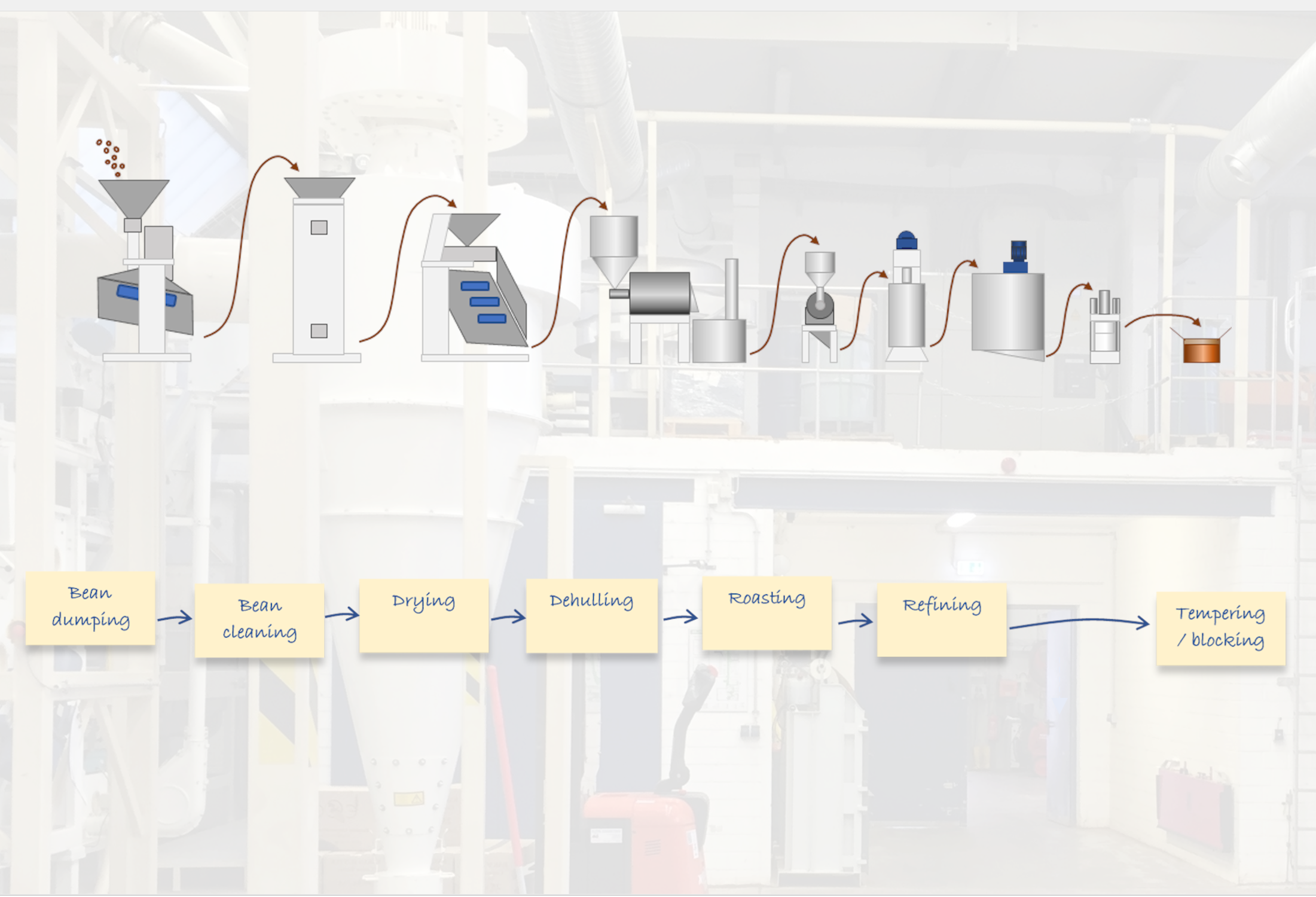

SMALL-SCALE PROCESSING

Small-scale processing is not just about shrinking machinery. Neither is it about inventing the wheel a second time. Rather it is about process and custom oriented solutions that are viable and functional. Based on a long experience of cocoa processing, small- and big-scale, in Europe as well as in cocoa growing countries, we strive to continuously improve small-scale processing specifications. This means to continuously keeping the mind open for new technologies and to test these according to given requirements.

We offer different solutions that are all based on an industrial engineering approach that considers GMP (good manufacturing practice) as well as HACCP. Our processing line-ups can be used either for high-quality bean-to-bar projects or for local processing projects in cocoa-growing regions. In this way an increased value addition of raw cocoa beans at a local level can be enabled. The resulting output is a high quality product, manufactured with high production standards.

For autonomous operation, we can offer renewable energy solutions that reduce the carbon footprint and assure an environmentally friendly production process.

Cocoa butter processing

Bean to Butter

- Complete processing lines for the processing of raw, uncleaned cocoa beans up to natural cocoa butter.

- Possibility of producing either liquid butter in tempered boxes or to fill up as blocks.

- Processing throughputs from 100 kg/h up to 500 kg/h or more.

- Based on the newest pressing technology, which enables a financially viable butter production for small throughputs (< 1,000 kg/h).

- Manual or semi-automatic operation including feeding and dosing equipment.

- Safe product debacterizing through the temerature controlled pressing process.

- Fully automatic tempering process, combined with a semi-automatic blocking unit to produce international standard cocoa liquor blocks.

- Optional with automatic press cake handling for bagging as pellets, coarse pre-grinding or with complete powder milling.

Cocoa liquor processing

Bean to Liquor

- Complete processing lines for the processing of raw, uncleaned cocoa beans up to cocoa liquor – liquid or tempered and moulded into 20-25 kg blocks.

- Processing throughputs from 100 kg/h up to 500 kg/h.

- Based on modern technologies with the best possible solution according to required throughput and raw materials.

- Manual or semi-automatic operation including feeding and dosing equipment.

- Safe product debacterizing thanks to an industrial nibs roasting technology with recipee controlled debacterizing and roasting process.

- Highly efficient grinding set up, which relies on a corundum pre-grinding stage combined with one or two vertical ball mill refiners.

- Fully automatic tempering process, combined with a semi-automatic blocking unit to produce international standard cocoa liquor blocks.

Chocolate, fillings and spreadings processing

Bean to Chocolate

- Complete processing lines starting from raw beans, nibs or cocoa liquor.

- Machinery throughputs starting at approximately 50 kg/h.

- Manual or semi-automatic operation with optional recipe and dosing control.

- Refining based on modern vertical ball mill refiners with product re-circulation and ventilation system to remove volatile acids.