MACHINERY FOR THE COCOA, NUTS AND CHOCOLATE PROCESSING

Foreign matters, such as stones, excessive dust or metal particles, may cause failures and lower the product quality. Therefore, it is important to remove any such impurities early in the process. We offer different solutions ranging from simple sorting tables for capacities of less than 50 kg/h or complete cleaning plants including pre-cleaner, destoner, metal separation and continuous weighing units for higher throughput capacities.

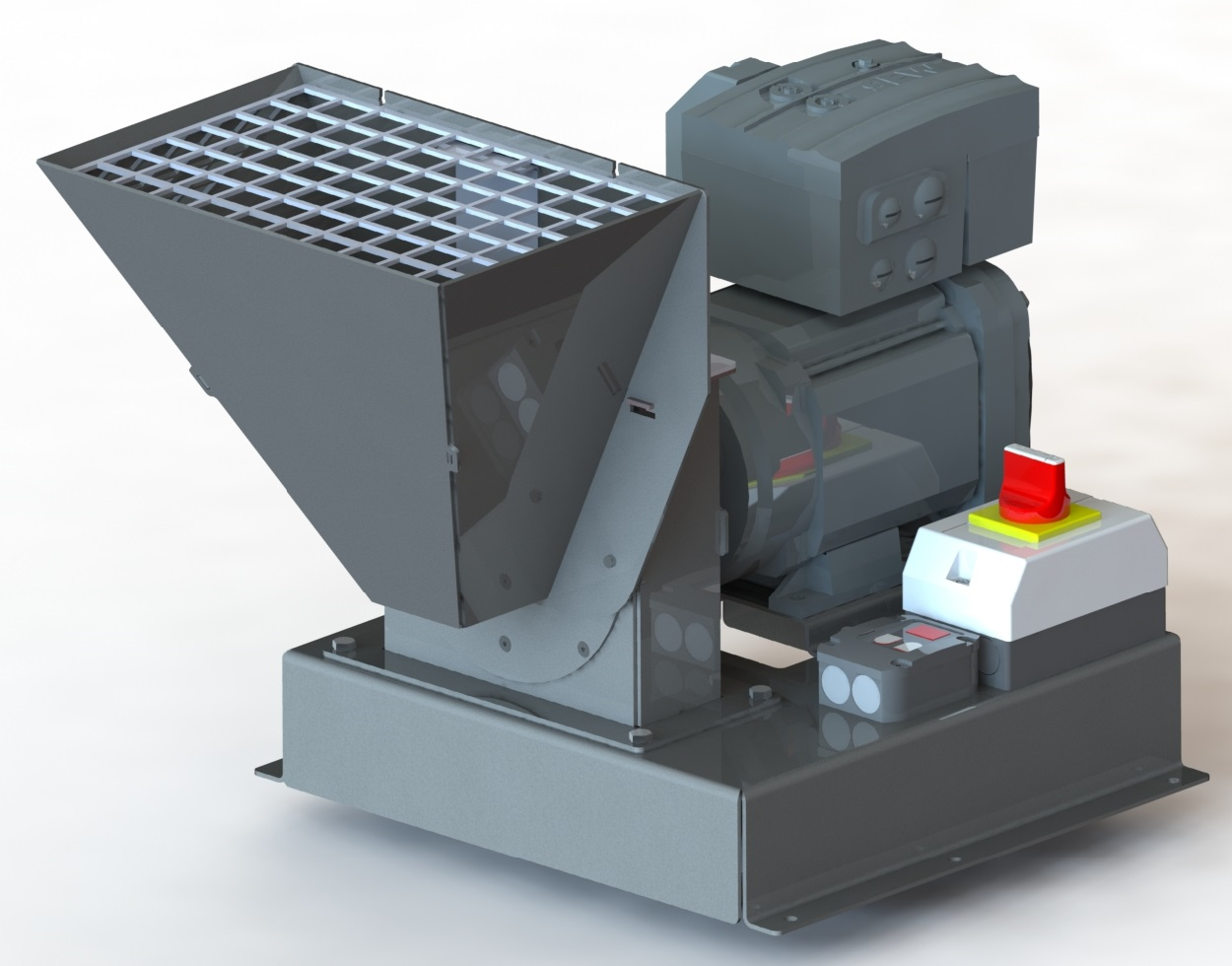

Bean cleaning for small capacities

Separate machinery or complete cleaning plants incl.:

– Cleaning drum to remove bigger impurities

– Destoner to remove stones and heavy impurities

– Magnetic separation for small metal particles

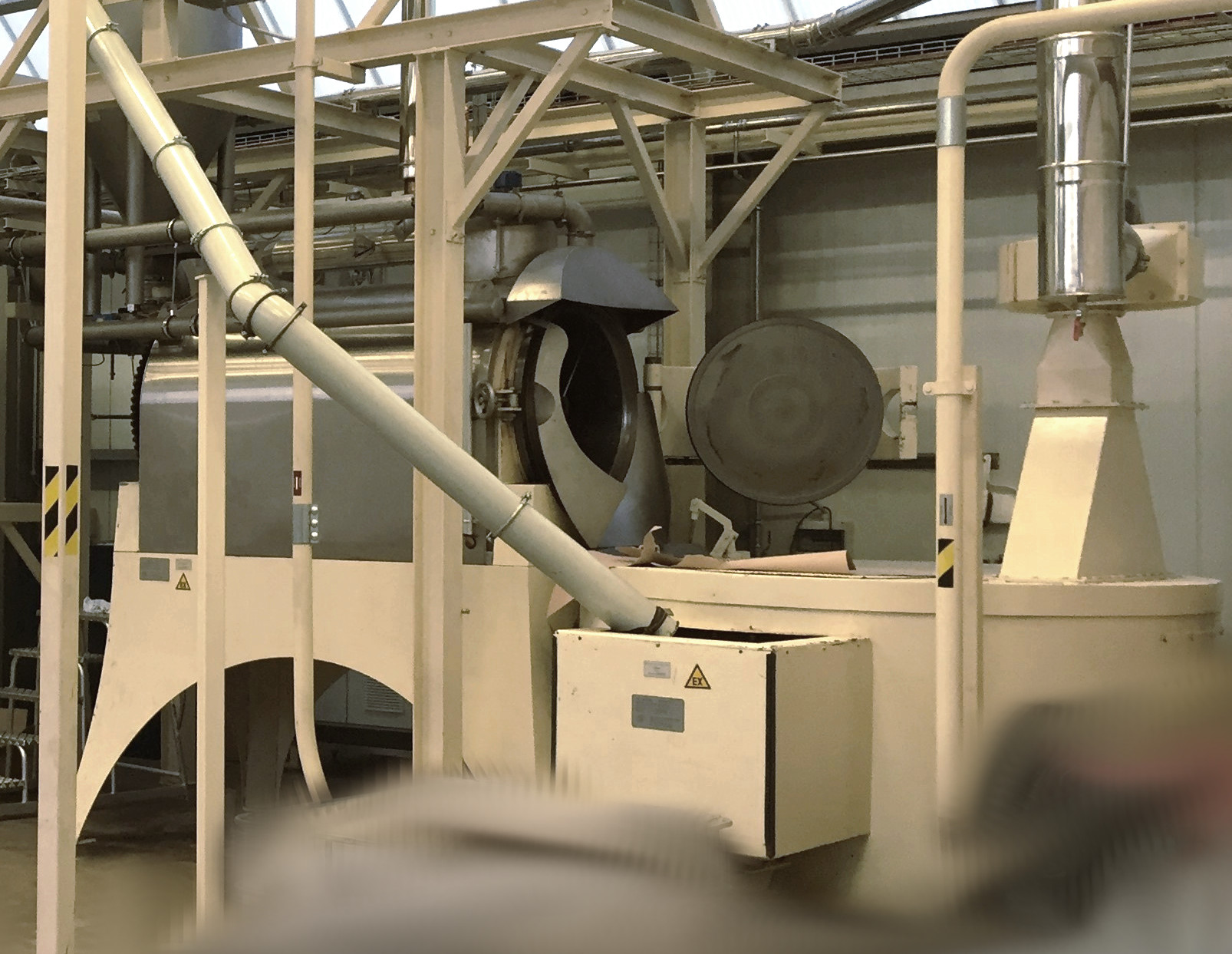

Bean cleaning plants > 300 kg/h

Separate machinery or complete cleaning plants incl.:

– Pre-cleaner to remove bigger impurities and dust

– Destoner or sorting machine to remove stones and heavy impurities

– Magnetic separation drum or metal detection unit for metal particles

– Automatic dosing and feeding with star-lock valves and conveying units

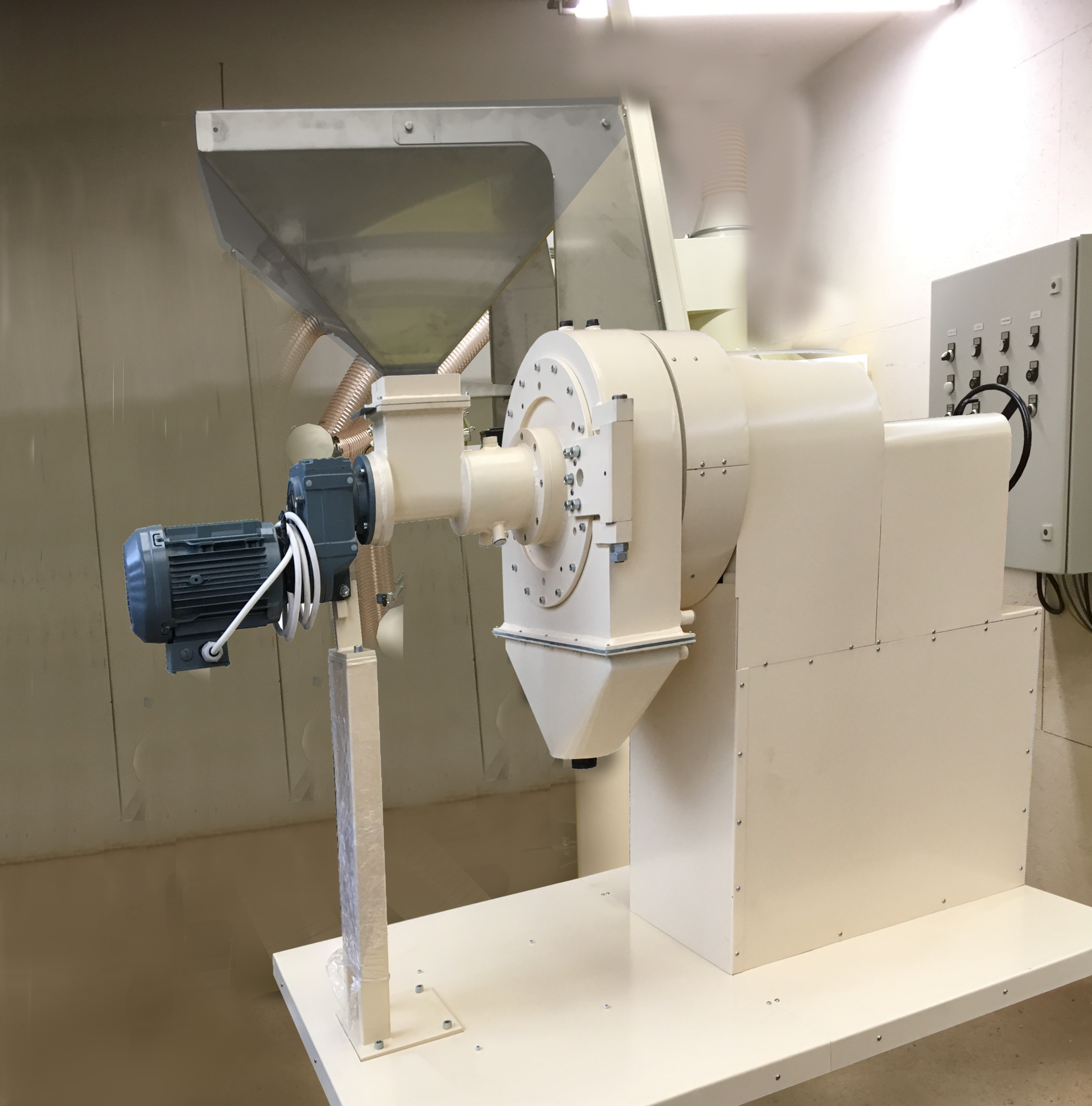

We can supply machinery for all processing steps, from cleaning and drying up to fine-grinding, chocolate refining or butter pressing. Our focus is customer oriented and so we are eager to know About your needs, your requirements and possible existing machinery. This helps us to offer a suitable solution for your case. This might concern reaching the optimal refining performance with our offer, depending on an existing pre-grinder or end-refiner. It could also concern the dimensioning of an offered Winnower depending on if beans or nibs roasting is practiced or if a pre-dryer is used.

Due to this, we talk less about standard solutions and more about custom oriented solutions. In terms of roasting we usually recommend beans roasting for smaller bean to bar projects, but nibs roasting for higher capacities. For refining we use industrial quality corundum grinders for the pre-grinding and vertical ball mills for the end-refining and chocolate refining.

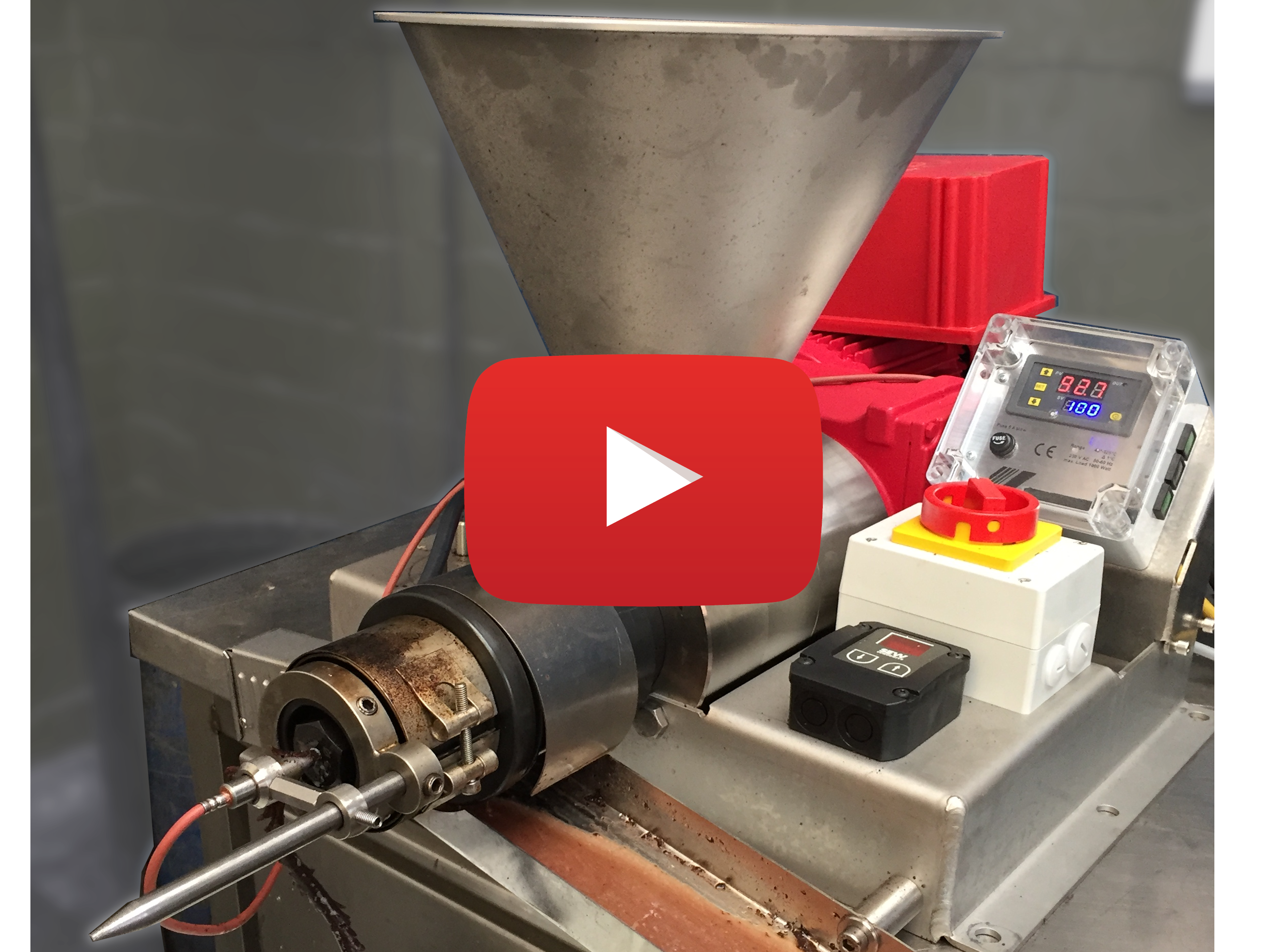

Since 2020 we can offer a new small-scale processing solution to extract cocoa butter, which makes this process viable also at a small scale with maintained product quality.